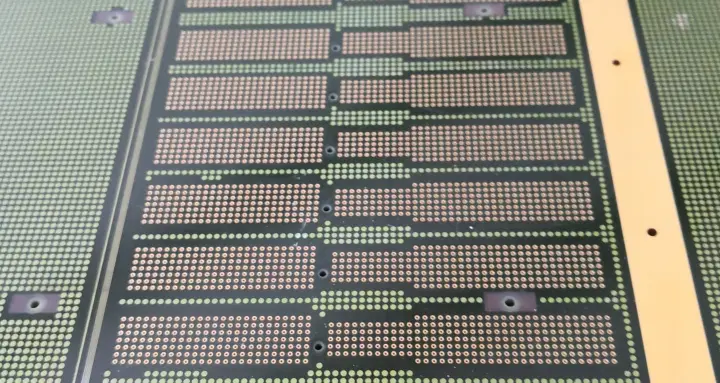

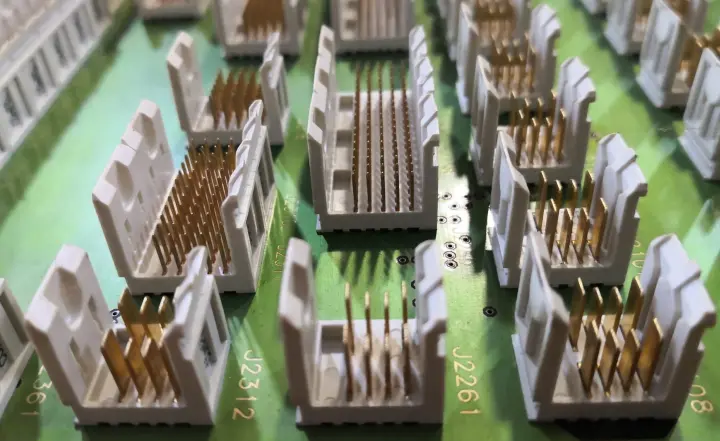

With this technology, components are not soldered to the PCBauch: gedruckte Schaltung, engl.: PCB – Printed circuit boar… More, but pressed into the metallized holes, enabling solder-free assembly. The electrical and mechanical connection depends on exact compliance with the tolerances specified by the component manufacturer. Different mechanical versions of the press-fit pins (elastic or solid) are available depending on the manufacturer.

The following information is required with the PCBauch: gedruckte Schaltung, engl.: PCB – Printed circuit boar… More data in order to be able to produce the holes for the press-fit components correctly:

- Clear labeling of the

drill holes for press-fit technology - diameter of the base hole,

without copper with tolerance specification - Final diameter incl.

Metallization with tolerance - Copper coating in the sleeve

- Coating thickness of the sleeve surface

This information can be found in the manufacturer’s data sheet for the relevant components.

For combinations of press-fit connectors and SMD components

sufficient distance must be ensured to enable mechanical relining. SMD components react partially

very critical to mechanical loads. The insertion forces of the press-fit connections must not generate any significant bending forces on the PCBauch: gedruckte Schaltung, engl.: PCB – Printed circuit boar… More.

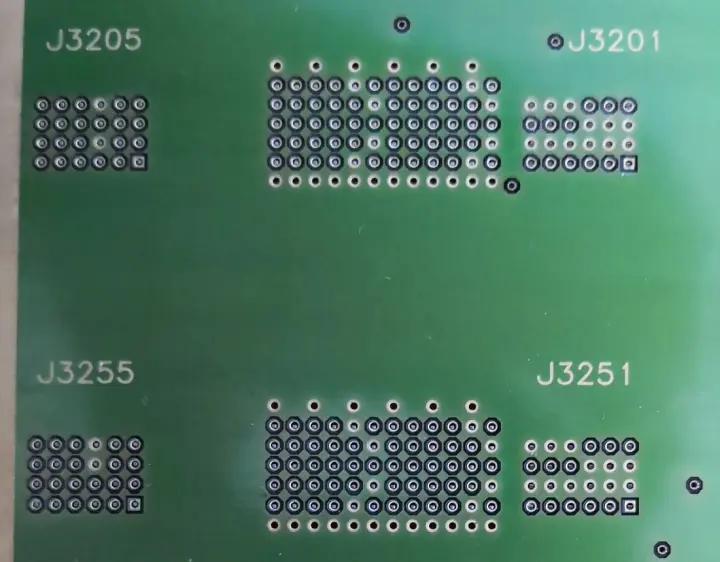

Example figures

| Specification | Example value |

|---|---|

| End hole+tolerance | 0,85mm +0,10/-0,05mm |

| Base hole+tolerance | 1,00mm ±0,025mm |

| Cu layer in drill hole | min. 25µm |

| Surface | ENIG |