Peelable Mask

Peelable mask is used to cover areas where solder is prevented from penetrating metallized holes or tinning solder pads during wave soldering. Furthermore, a peelable mask can be used in the area of gold contacts or carbon elements. The peelable mask can withstand the PCBauch: gedruckte Schaltung, engl.: PCB – Printed circuit boar… More being heated twice without peeling off.

After the soldering process, the mask can be removed from solder pads and plated-through holes without leaving any residue.

Caution: No peelable mask should be applied to non-plated-through holes, slots or contours, as residue-free removal cannot be guaranteed.

| Property | Standard | |

|---|---|---|

|

|

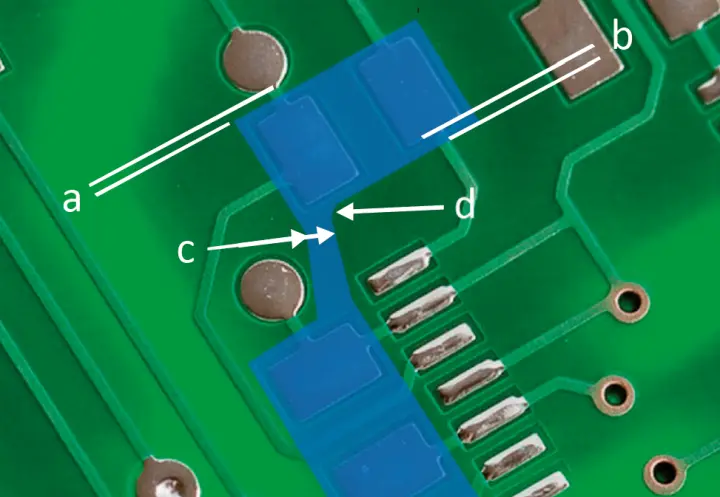

a | ≥0,5mm |

| Overlap Peelable mask | b | ≥0,5mm |

| Min. bridge wdth | c |

≥1,5mm Recommendation: ≥2mm |

| Internal angle/corners | d |

≥90° Recommendation: Rounded |

These recommendations do not represent the technological limits.

Please discuss this with the manufacturer.

To avoid excessive paint flow and paint leakage on the opposite side, drill holes with a diameter of > >1.0 mm should not be completely covered by strippable paint. Complete coverage (closure) cannot be guaranteed for holes > >2.0mm. We recommend covering these holes with capton tape.

Carbon print

Carbon pastes are fine or coarse-grained graphite pastes that are applied by screen printing as keyboard contacts, LCD contacts or LCD strips. There are basically two types:

- Resistive graphite printing for sliding contacts

- Conductive graphite printing for membrane contacts

Due to the requirements for carbon print, a minimum copper thickness of 17.5μm is required. A peelable mask (see above) can also be applied to protect the carbon layer.

In the Gerber data, the data for the carbon print (here: gray) should be output as a separate file.

List of data

- Contour (light gray)

- Copper (red)

- Legendprint (white)

- Carbon print (grey)