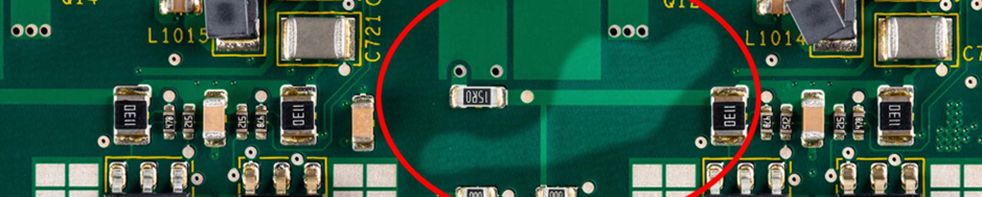

Delamination on a circuit board occurs when the individual layers of the circuit board are no longer properly connected to each other. The layers can become detached or flake off, which leads to an impairment of the structural integrity of the PCBauch: gedruckte Schaltung, engl.: PCB – Printed circuit boar… More.

There can be several causes of delamination, including

- Moisturebold

, moisture is trapped during the manufacturing process or later penetrates the PCBauch: gedruckte Schaltung, engl.: PCB – Printed circuit boar… More, this can lead to delamination.

For information on humidity, please refer to the Storage section. - Poor adhesion

Insufficient adhesion between the materials or unequal thermal expansion coefficients of the materials used can lead to delamination. - Defective manufacture

Problems during the production process such as incorrect temperature settings, uneven pressure distribution or impurities can contribute to delamination.

Delamination is a serious quality problem as it can affect the electrical performance of the PCBauch: gedruckte Schaltung, engl.: PCB – Printed circuit boar… More. This can lead to interruptions in the electrical flow, signal loss or even failure of the entire component. In many cases, a damaged circuit board is no longer functional and must be replaced.