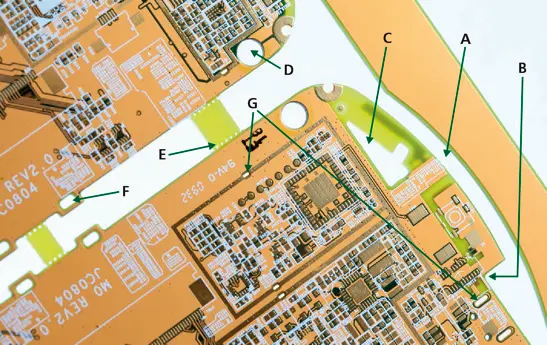

Milling

The external contours, internal cut-outs and larger holes are usually milled using a CNC-controlled machine.

Please refer to the separate page on the subject of “breaking points” for panel variants.

| Property | Definition | |

|---|---|---|

| A | Outside contour milling | Standard with 2.0 or 2.4 mm diameter |

| B | Inside corner (90° milling) | Rounding has the radius of the milling diameter |

| C | Inner contour | Through-plated also possible |

| D | Hole milling | Holes with Ø >6mm are milled |

| E | Breaking Points | Drilling-milling combination for subsequent cutting |

| F | Slot milling NDK | Not plated through, carried out during the milling process |

| G | Slot milling DK | Plated-through slots or edges are milled during the drilling process |

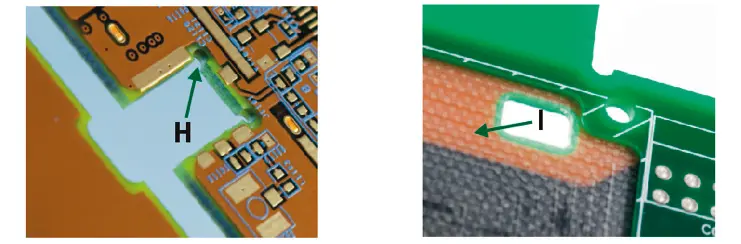

| H | Auxiliary hole for 90° milling | To avoid the inner radius and to obtain exact 90° angles, auxiliary holes are recommended |

| I | Z-axis milling / Level milling | Level milling (depth milling) is possible by means of Z-axis control. also possible on a larger area |