Solder resist

The terms “solder resist” or “solder mask” are often used when referring to any type of permanent or temporary polymeric resist coating material. Solder resists are used to limit and control the application of solder to selected areas of the PCBauch: gedruckte Schaltung, engl.: PCB – Printed circuit boar… More during soldering operations during assembly. Solder resists are used to control and limit surface contamination of PCBauch: gedruckte Schaltung, engl.: PCB – Printed circuit boar… More surfaces during soldering and subsequent processing and are sometimes used to reduce the growth of dendritic threads between conductive patterns on the surface of the PCBauch: gedruckte Schaltung, engl.: PCB – Printed circuit boar… More base material. Detailed specifications and information regarding the requirements for solder resists can be found in IPC-6012 and IPC-SM-840.

For standard-class PCBs, mask-defined screen printing is a suitable method for applying the solder resist. For finer structures such as SMD technology, on the other hand, a photosensitive solder resist is preferably used in spray or curtain casting processes or even screen printing. In future, it will be possible to apply this using the inkjet printing process.

Special colours for the solder resist, such as red, blue, white, black or colourless, are applied exclusively by screen printing. The typical thicknesses over the conductors are between 7 and 10 μm with a base copper thickness of 18µm. If the base copper is thicker, the thickness of the solder resist can vary accordingly.

Edge coverage of the sheets and pads of at least 3 to 5 μm is generally recommended to ensure optimum protection.

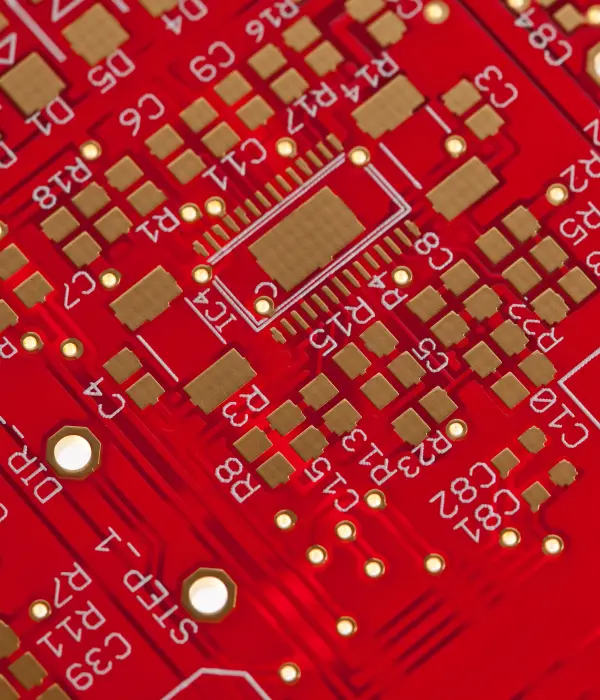

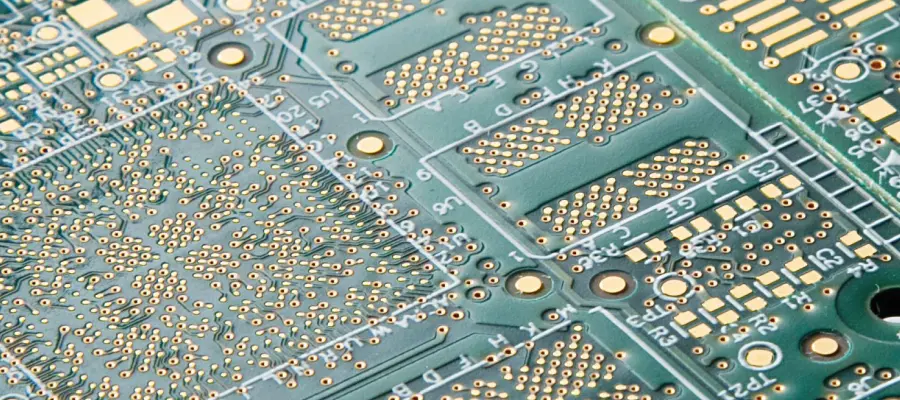

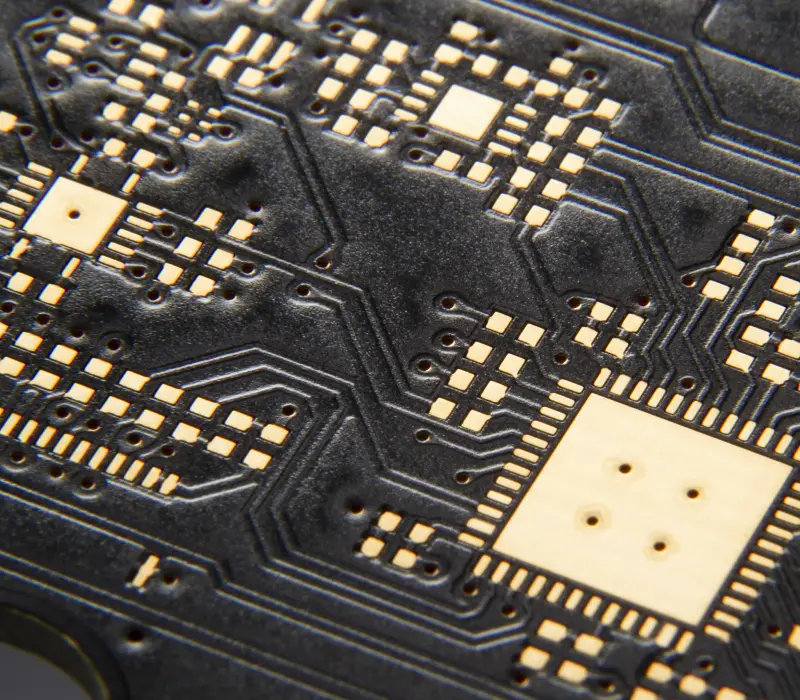

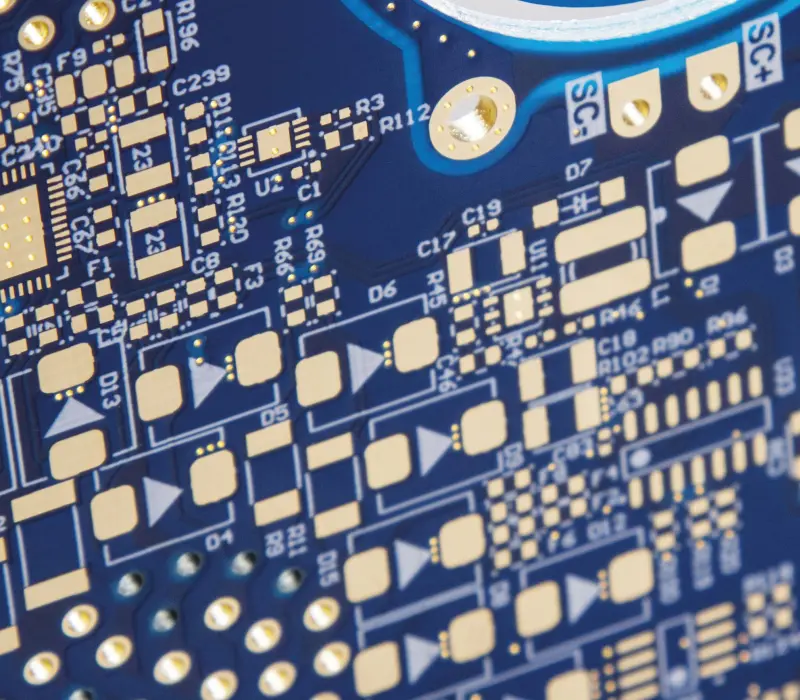

Sample images

Countless variations of solder resist lacquers and colours make our world more colourful!

Overview of properties

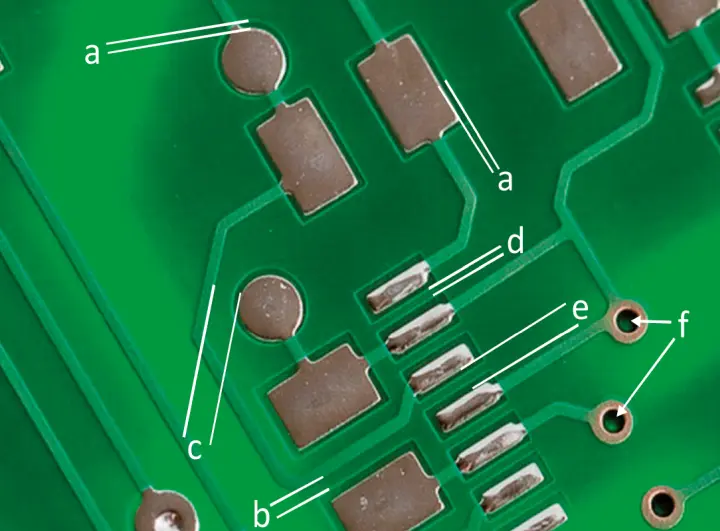

| Property | Standard | Fine | Finest | High End | |

|---|---|---|---|---|---|

| Cutout | a | ≥0,1mm | ≥0,08mm | ≥0,05mm |

in consultation with the respective manufacturer |

|

Mask/conductor |

b | ≥0,1mm | ≥0,075mm | ≥0,05mm | |

| Copper/copper distance* | c | ≥0,2mm | ≥0,15mm | ≥0,1mm | |

| width of bridge | d | ≥0,15mm | ≥0,1mm | ≥0,05mm | |

| Pad/pad distance* | e | ≥0,3mm | ≥0,25mm | ≥0,15mm | |

| Vias | f | see separate topic on vias/viafilling | |||

*For the realization of the solder bridges. Highly dependent on the required copper thickness and solder resist color

Note:

Recommendations do not represent the technological limits. Please discuss this with the respective manufacturer.