Welcome to the PCBworld website, where we present you with a wide range of information and products. The product range comprises four main groups, which form the core of our services and products: PCBs, PCBA, SMT stencils and enclosures. These product groups form the basis for the manufacture of high-quality electronic devices and offer a wide range of possibilities for the development and production of electronics projects.

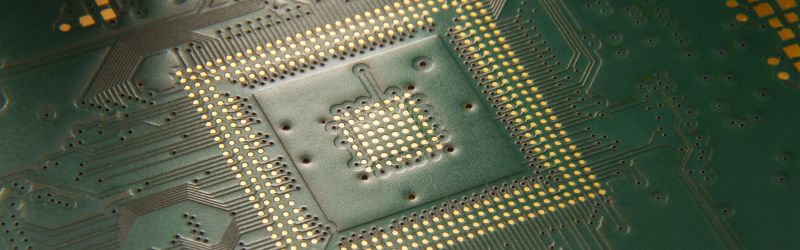

PCB

Printed circuit boards are the heart of electronic circuits and form the basis for the integration of components. Our printed circuit boards are of the highest quality and can be tailored to your individual requirements. Whether individual items, prototypes or mass production, we offer the right solutions. You will find a wealth of information on our website, from insulation boards without copper to complex multilayerMultilayer (Mehrschicht-Technologie):Die Multilayer-Technolo… More structures.

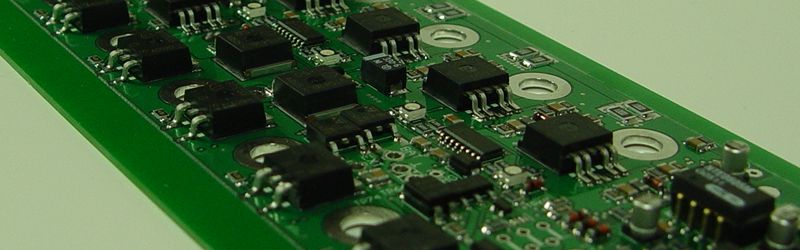

PCBA

The assembly of printed circuit boards is a crucial step in electronics production. Our experts ensure that your components are placed precisely and efficiently to ensure perfect functionality. We offer both automated and manual placement services, depending on the requirements of your project.

SMT-stencil

SMT stencils are an indispensable tool for the precise processing of surface mount components. Our high-quality stencils ensure precise placement of the components, which leads to improved quality and efficiency in production. We offer customized SMT stencils that are perfectly tailored to your needs.

Enclosures

The right enclosure is crucial for protecting your electronic devices and improving their aesthetic appearance. We offer a wide range of enclosures in various sizes and designs to meet your individual requirements.

Whether you are an electronics developer, a prototype builder or a manufacturer of electronic devices, our PCBauch: gedruckte Schaltung, engl.: PCB – Printed circuit boar… More, PCBA, SMT stencil and enclosure product groups are designed to make your projects a success. Browse through our range and contact us to find out more about our high-quality products and services. We are here to help you realize your electronic visions.

PCB

PCBA

SMT-stencil

Enclosures

Printed circuit boards, also known as PCBs, are critical components in electronic devices. These flat, insulated boards serve as the basis for connecting and mounting electronic components such as chips, resistors and capacitors. Conductor tracks made of copper, arranged in a complex network, enable the transmission of electrical current and data between the components.

Printed circuit boards are available in various shapes and sizes and can be single-sided, double-sided or multi-layered, depending on the requirements of the particular application. They are indispensable in modern electronic devices, from smartphones and laptops to industrial control systems.

The development of PCBauch: gedruckte Schaltung, engl.: PCB – Printed circuit boar… More technologies has revolutionized the electronics industry by enabling the miniaturization of devices and improving the performance and reliability of electronic devices. In the future, printed circuit boards will continue to play a key role in the electronics industry as the demand for ever smaller, more powerful and energy-efficient devices continues to grow.

PCBauch: gedruckte Schaltung, engl.: PCB – Printed circuit boar… More assembly is a crucial step in the manufacture of electronic devices. In this process, electronic components such as microchips, resistors, capacitors and other components are mounted on a circuit board to create a functional electronic device. Assembly is carried out according to a carefully designed circuit diagram, which specifies the exact position and connection of the components on the circuit board.

There are two main methods of PCBauch: gedruckte Schaltung, engl.: PCB – Printed circuit boar… More assembly: manual assembly and automated assembly. With manual assembly, the components are placed by hand, which is common for small quantities or prototype designs. Automated assembly, on the other hand, is used in mass production, where specialized machines place the components precisely and efficiently.

The quality of PCBauch: gedruckte Schaltung, engl.: PCB – Printed circuit boar… More assembly is crucial for the performance and reliability of the end product Incorrect assembly can lead to malfunctions. Therefore, various test procedures such as AOI (Automated Optical Inspection) and functional tests are used to ensure that all components are correctly positioned and function properly.

Overall, PCBauch: gedruckte Schaltung, engl.: PCB – Printed circuit boar… More assembly is a critical step in electronics manufacturing that requires high-precision equipment and expertise to ensure high-quality products.

SMT stencils, also known as soldering stencils or stencils, play an important role in the manufacture of printed circuit boards and electronic devices. These thin metal plates, often made of stainless steel or nickel, are provided with precise openings that correspond exactly to the positions of the SMD (surface mount device) components on a circuit board. These stencils are used in the reflow soldering process to precisely apply solder paste to the PCBauch: gedruckte Schaltung, engl.: PCB – Printed circuit boar… More before the SMD components are placed.

The selection and manufacture of SMD stencils is of great importance as they influence the soldering quality and reliability of the end product. The openings in the stencil must be precisely aligned with the components to ensure that the solder paste is applied in the correct quantity and position. This ensures a secure connection between the components and the PCBauch: gedruckte Schaltung, engl.: PCB – Printed circuit boar… More.

SMT stencils are often manufactured precisely using CNC machines in order to achieve the required accuracy. They are crucial for the mass production of electronic devices and ensure consistent quality and repeatability in the manufacturing process. Overall, SMT stencils are a key component in the production of printed circuit boards and contribute to the efficiency and reliability of electronic devices.

Enclosures for electronics manufacturing are essential components that protect, organize and make electronic devices aesthetically pleasing. These covers or casings are used to protect the internal electronic components from external influences such as dust, moisture, shocks and electromagnetic interference. Enclosures are manufactured in various sizes, shapes and materials to meet the specific requirements of different applications.

Typically, enclosures are made of plastic, metal or aluminum, with each material having different advantages and disadvantages in terms of durability, heat dissipation and cost. The design of enclosures also takes into account aspects such as the arrangement of interfaces, ventilation slots and mounting options for circuit boards and components.

Furthermore, enclosures play an important role in the aesthetic design of electronic devices and influence the user experience. They can emphasize the brand and identity of a product. Overall, enclosures are of crucial importance in electronics production, as they have a significant influence on the functionality, safety and appearance of electronic devices.